Plumbing can be a daunting task, with its intricate network of pipes and countless fittings. But have you ever wondered what truly makes it the hardest part of any construction project? From battling cramped spaces to deciphering an endless maze of blueprints, the challenging nature of plumbing lies in its ability to push your problem-solving skills to the limit. In this article, we will explore the various obstacles that plumbers face, and uncover the secrets behind this complex and vital trade. So, if you’ve ever been curious about what it takes to conquer the plumbing world, read on to discover the answer to the age-old question: what is the hardest part of plumbing?

Understanding Plumbing Systems

Plumbing systems are an essential part of any building, whether residential or commercial. As a homeowner or a professional plumber, it is crucial to have a comprehensive understanding of different plumbing systems. This knowledge will enable you to effectively maintain and repair plumbing issues.

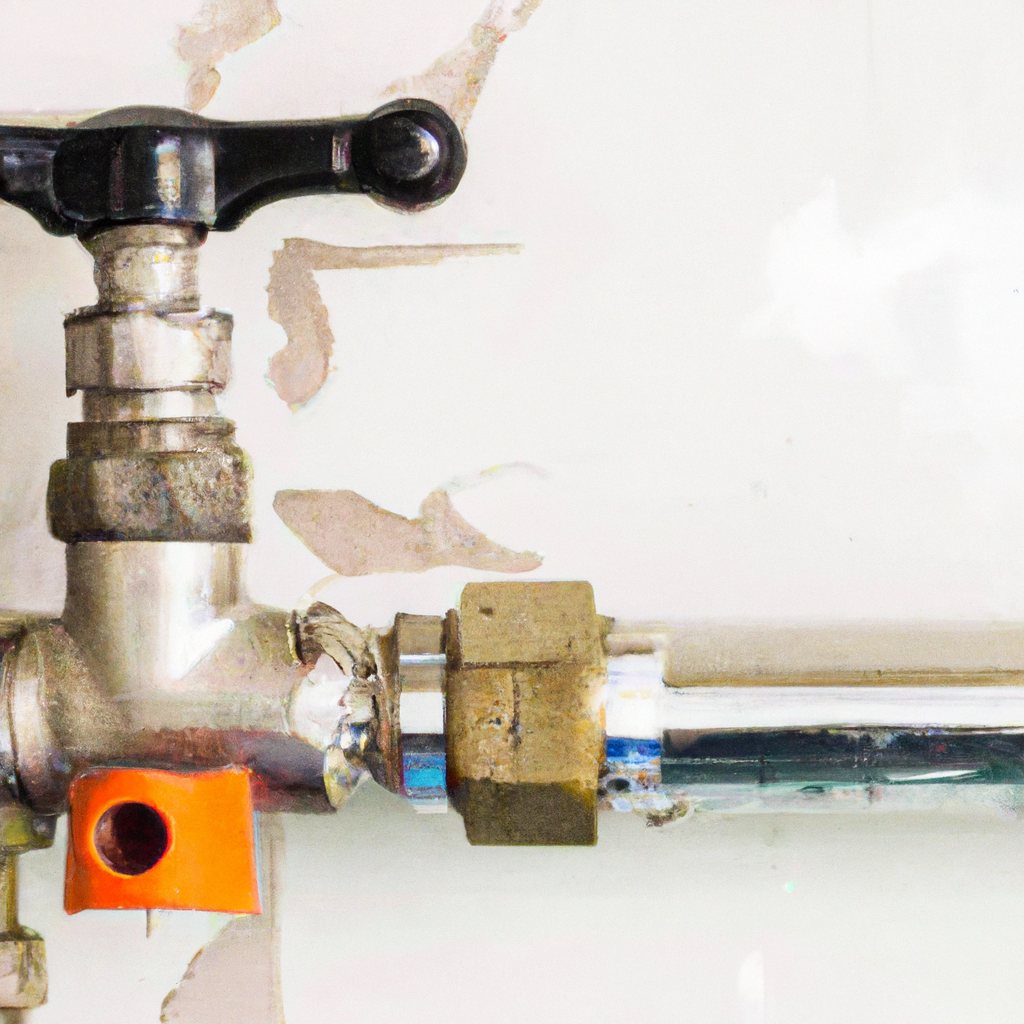

Understanding various plumbing systems involves familiarizing yourself with the different types of pipes and fixtures used in buildings. There are several types of plumbing systems, including water supply systems, drainage systems, and sewer systems. Each system has its specific components and functions, and it’s important to understand how they work together.

Knowledge of various plumbing systems

In order to work effectively as a plumber, you need to have a solid understanding of the different types of plumbing systems commonly found in buildings. This knowledge will help you diagnose and fix issues more efficiently.

Water supply systems, for example, consist of pipes that deliver clean water to different parts of the building. Understanding how these pipes are installed and connected is essential when it comes to repairing leaks or replacing fixtures.

Drainage systems, on the other hand, are responsible for ensuring that wastewater is safely removed from the building. Knowing the layout of the drainage system will allow you to identify problems such as blockages or leaks and provide appropriate solutions.

Sewer systems play a vital role in transporting wastewater from the building to the municipal sewer line. Familiarizing yourself with the sewer system’s components and the relevant regulations will help you address issues like backups or damaged pipes effectively.

Understanding plumbing codes and regulations

Plumbing codes and regulations are guidelines set by local authorities to ensure that plumbing systems are installed correctly and function safely. It is crucial to have a comprehensive understanding of these codes to comply with legal requirements and ensure the safety of the occupants.

By staying updated on the latest plumbing codes and regulations, you can ensure that your work meets the required standards. This includes understanding the appropriate pipe sizes, materials, and installation methods for different applications.

Furthermore, plumbing codes also include regulations related to water conservation and energy efficiency. As a responsible plumber, you need to be aware of these regulations to help clients save water and energy, and contribute to sustainable plumbing practices.

Identifying and Diagnosing Issues

A significant aspect of being a plumber is the ability to identify and diagnose plumbing issues accurately. This requires attention to detail and a systematic approach to problem-solving.

Locating hidden leaks

One of the most challenging tasks for plumbers is locating hidden leaks. Leaks can occur in various places, including behind walls, under floors, or in inaccessible areas. Detecting hidden leaks often requires specialized equipment and techniques.

Experienced plumbers can use methods such as thermal imaging or acoustic detectors to locate hidden leaks. By accurately identifying the source of the leak, they can minimize damage to the building and perform repairs efficiently.

Identifying pipe blockages

Another common issue plumbers face is identifying pipe blockages. Blockages can occur due to various reasons, including the buildup of debris, mineral deposits, or foreign objects. Locating blockages is essential to restore the proper flow of water and prevent further damage.

Plumbers use a range of tools to identify pipe blockages, including drain cameras and pipe inspection equipment. These tools allow them to visually inspect the pipes and pinpoint the location of the blockage. Once identified, the plumber can employ the appropriate techniques to remove the blockage and restore the normal flow.

Diagnosing complex plumbing problems

Not all plumbing issues are straightforward. Some problems require advanced diagnostic skills to identify and resolve. These complex plumbing problems often involve multiple components and systems, requiring a deep understanding of how they interact.

Experienced plumbers have the expertise to diagnose complex problems that may involve multiple symptoms or hidden causes. By conducting thorough inspections, testing various components, and analyzing system behavior, they can determine the root cause of the issue and provide effective solutions.

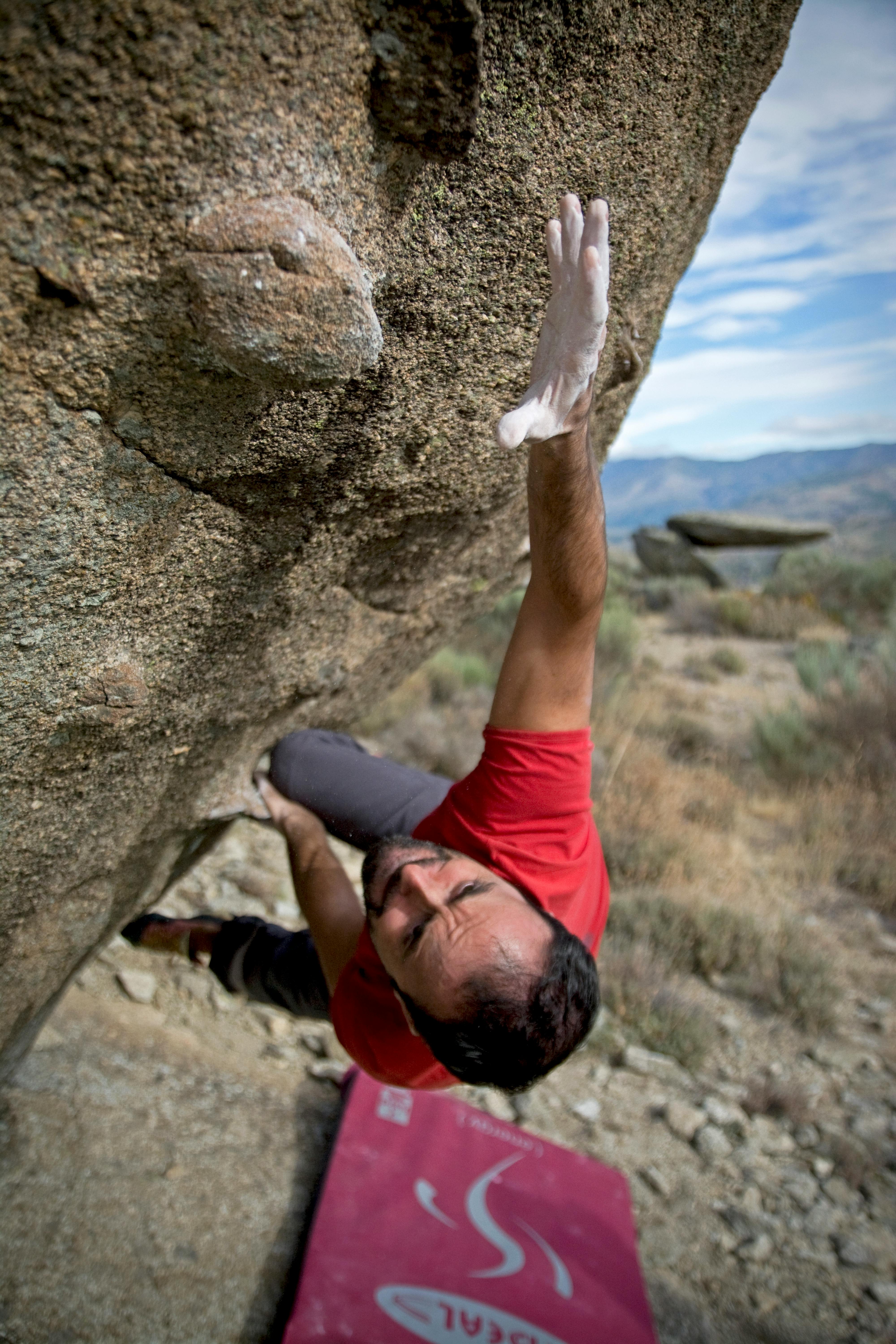

Working with Different Types of Pipes

Plumbers encounter various types of pipes in their line of work, each with its unique characteristics and installation methods. Understanding the different pipe materials and knowing how to work with them is essential for successful plumbing repairs and installations.

Understanding different pipe materials

Pipes can be made from various materials, including copper, PVC (Polyvinyl Chloride), galvanized steel, and cast iron. Each material has its advantages, disadvantages, and specific applications. Familiarizing yourself with these materials is crucial for selecting the appropriate pipe material for different plumbing systems.

Copper pipes, for example, are known for their durability and resistance to corrosion. They are commonly used for water supply lines and have been a popular choice for many years.

PVC pipes, on the other hand, are lightweight, easy to install, and resistant to chemicals. They are commonly used for drainage and venting systems due to their affordability and versatility.

Galvanized pipes are made from steel coated with a layer of zinc, providing protection against corrosion. While they were widely used in the past, they have become less common due to health concerns and other disadvantages.

Cast iron pipes are known for their durability and sound insulation properties. They are commonly found in older buildings and are often used for soil and waste lines.

By having a thorough understanding of these different pipe materials, you can make informed decisions about which pipes to use and how to work with them effectively.

Working with copper pipes

Copper pipes are widely used in plumbing due to their durability, reliability, and resistance to corrosion. When working with copper pipes, it is essential to understand the different types and sizes of copper pipes available.

Plumbers need to know how to join copper pipes using various methods such as soldering, compression fittings, or push-fit connectors. Properly joining copper pipes ensures leak-free connections and prevents future issues.

In addition to joining techniques, understanding how to cut and bend copper pipes accurately is crucial. Specialized tools such as pipe cutters and pipe benders are used to achieve precise cuts and bends, allowing plumbers to navigate around obstacles and create a reliable plumbing system.

Working with PVC pipes

PVC pipes are a popular choice for drainage and venting systems due to their affordability, versatility, and ease of installation. When working with PVC pipes, it is crucial to have the right tools and techniques to ensure proper installation and long-lasting performance.

Plumbers need to understand how to cut PVC pipes accurately using tools such as PVC pipe cutters or hacksaws. Smooth and clean cuts are essential to create leak-free connections and prevent future issues.

Joining PVC pipes typically involves using solvent cement or threaded fittings, depending on the application. Knowing how to apply solvent cement correctly and create strong connections is essential for a reliable plumbing system.

Furthermore, understanding the necessary support and anchoring requirements for PVC pipes is crucial to prevent sagging or movement over time. Properly securing PVC pipes ensures the integrity of the system and avoids potential issues.

Working with galvanized pipes

Although galvanized pipes are less commonly used today, they can still be found in older buildings. Working with galvanized pipes requires understanding the unique characteristics of this material and the potential challenges it presents.

Galvanized pipes can be more challenging to cut and join compared to other pipe materials. Plumbers need to use appropriate tools such as pipe cutters or reciprocating saws, as well as threaded fittings to achieve secure connections.

However, working with galvanized pipes can present health concerns due to the potential for lead contamination. It is crucial to take appropriate safety precautions, such as wearing gloves and avoiding the ingestion of lead-containing dust particles.

Working with cast iron pipes

Cast iron pipes are known for their durability and longevity, making them common in older buildings. When working with cast iron pipes, plumbers need to be familiar with the specific techniques and tools required for this material.

Cutting cast iron pipes can be challenging due to their thickness and strength. Plumbers often use specialized tools such as reciprocating saws or snap cutters to make clean cuts without damaging the pipe.

Joining cast iron pipes typically involves using no-hub couplings or mechanical couplings. These connections require careful alignment and tightening to ensure a secure and leak-free joint.

Working with cast iron pipes can also involve addressing issues such as corrosion and rust. Plumbers need to understand the appropriate steps to repair or replace damaged sections of cast iron pipes to ensure the longevity of the plumbing system.

Handling Drainage Problems

Drainage problems can be frustrating and disruptive to daily life. As a plumber, being able to effectively handle drainage issues is essential to restore the proper functioning of the plumbing system.

Unclogging drains

Unclogged drains are one of the most common plumbing issues homeowners face. Blockages can occur due to a buildup of hair, soap scum, food particles, or other debris. As a plumber, you need to have the skills and tools to unclog drains efficiently.

One common method of unclogging drains is using a plunger. By creating a suction effect, plungers can dislodge minor blockages and restore the normal flow. It is essential to use the right type of plunger and apply the correct technique for maximum effectiveness.

For more stubborn or severe blockages, plumbers may use tools such as drain snakes or augers. These tools allow them to physically break up or remove the blockage, enabling the water to flow freely.

To prevent future drain blockages, plumbers may also recommend regular maintenance, such as using drain covers or installing hair traps to catch potential debris before it enters the drain.

Dealing with sewer line backups

Sewer line backups are a more severe and complex drainage problem. When the main sewer line becomes clogged or damaged, it can cause sewage to back up into the building, leading to health hazards and extensive damage.

Handling sewer line backups requires advanced knowledge and specialized equipment. Plumbers may use video inspection equipment to assess the extent and location of the backup. This allows them to determine the most effective solution, whether it is clearing the blockage or repairing damaged sections of the sewer line.

In some cases, sewer line backups may require excavation and replacement of the affected pipes. Plumbers need to be proficient in excavation techniques and understand the necessary safety precautions to carry out the repairs effectively.

Repairing and replacing damaged drain pipes

Damaged drain pipes can cause leaks, foul odors, and other problems in the plumbing system. As a plumber, being able to repair or replace damaged drain pipes is crucial to restore the proper functioning of the system.

Repairing drain pipes often involves identifying the source of the damage, whether it is a crack, corrosion, or a joint failure. Once the cause is determined, appropriate repair techniques can be employed, such as patching the damaged area or applying epoxy coatings.

In some cases, replacing the damaged drain pipe may be necessary. Plumbers need to have the skills to remove the old pipe, select the appropriate replacement, and properly install it to ensure a leak-free and reliable connection.

Regular maintenance and inspections are also essential to identify potential issues before they become severe. Plumbers can recommend preventative measures and perform routine maintenance to extend the lifespan of drain pipes and prevent costly repairs.

Repairing and Replacing Fixtures

Fixtures such as faucets, toilets, showerheads, and water heaters are an integral part of any plumbing system. Over time, these fixtures may develop issues that require repair or replacement.

Repairing or replacing faucets

Leaking or malfunctioning faucets are a common plumbing issue that can waste water, increase utility costs, and cause inconvenience. The ability to diagnose and repair faulty faucets is a valuable skill for a plumber.

Repairing faucets typically involves identifying the cause of the leak, whether it is a worn-out washer, a faulty cartridge, or a loose connection. Once the problem is identified, the appropriate repair method can be applied, such as replacing the faulty part or tightening the connections.

In some cases, faucets may be beyond repair and need to be replaced. Plumbers need to have the expertise to remove the old faucet, select a suitable replacement, and install it correctly. Proper installation ensures efficient water flow and prevents future leaks.

Fixing leaking toilets

Leaking toilets can waste significant amounts of water and cause water damage in the bathroom. Being able to identify and fix leaking toilets is crucial for a plumber.

To diagnose a leaking toilet, plumbers often perform a dye test. By adding dye to the toilet tank, they can determine if water is leaking into the bowl, indicating a faulty flush valve or flapper.

Repairing a leaking toilet may involve replacing a worn-out flapper, adjusting the fill valve, or tightening connections. It is important to identify the specific cause of the leak to ensure an effective repair.

In some cases, a leaking toilet may require the replacement of the entire flushing mechanism. Plumbers need to have the knowledge and skills to remove the old mechanism and install a new one, restoring the toilet’s proper function.

Replacing showerheads

Over time, showerheads may become clogged with mineral deposits, affecting water flow and the showering experience. Being able to replace showerheads is a common task for a plumber.

To replace a showerhead, plumbers need to remove the old showerhead by unscrewing it from the shower arm. They then select a suitable replacement showerhead and install it, ensuring a snug and leak-free connection.

Replacing a showerhead can also be an opportunity to upgrade to a more water-efficient showerhead, helping homeowners save water and reduce their utility bills. Plumbers can provide recommendations for water-saving showerheads and install them as part of their service.

Repairing or replacing water heaters

Water heaters play a crucial role in providing hot water for various household tasks. When water heaters develop issues, being able to repair or replace them is essential to restore hot water supply.

Repairing a water heater often involves identifying the specific problem, whether it is a faulty thermostat, a malfunctioning heating element, or a leaky pressure relief valve. Once the cause is determined, plumbers can apply the appropriate repair technique, such as replacing the faulty component or adjusting the settings.

In some cases, a water heater may be beyond repair and require replacement. Plumbers need to have the expertise to disconnect the old water heater, select a suitable replacement with the appropriate capacity, and install it correctly. Proper installation ensures safe operation and efficient hot water supply.

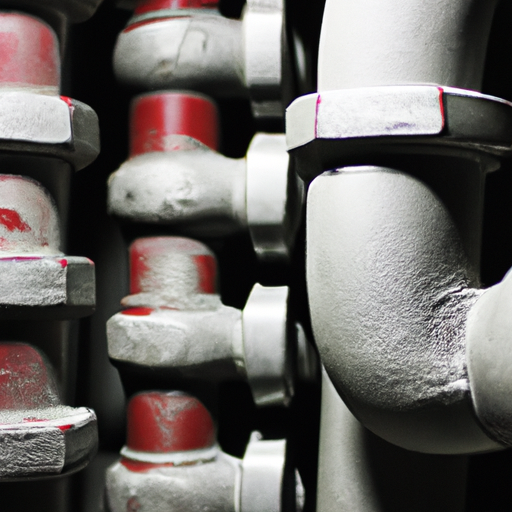

Dealing with Water Pressure Issues

Water pressure plays a crucial role in the performance of a plumbing system. Issues related to low or high water pressure can affect the functionality of fixtures and appliances. Being able to diagnose and address water pressure issues is essential for a plumber.

Diagnosing low water pressure

Low water pressure can be frustrating when performing daily tasks such as showering or washing dishes. As a plumber, being able to diagnose the cause of low water pressure accurately is essential for effective repairs.

Low water pressure can be caused by various factors, including clogged pipes, sediment buildup, or a faulty pressure regulator. Plumbers need to assess the plumbing system, check for potential restrictions, and investigate the cause of the low water pressure.

Depending on the cause, plumbers can employ different techniques to address low water pressure issues. This may include cleaning or replacing clogged pipes, flushing out sediment, or adjusting or replacing the pressure regulator.

Handling high water pressure

High water pressure can cause excessive stress on plumbing pipes, fixtures, and appliances, leading to leaks, bursts, or premature failure. Being able to assess and handle high water pressure is essential to prevent costly damage.

Plumbers can use pressure gauges or other measuring devices to determine if the water pressure exceeds the recommended levels. If high water pressure is detected, they can install or adjust pressure regulating valves to reduce the pressure to a safe and optimal level.

Working with pressure regulating valves requires knowledge of the specific valve type, installation techniques, and the recommended pressure settings. By effectively managing high water pressure, plumbers help extend the lifespan of plumbing components and minimize the risk of costly repairs.

Fixing water pressure regulators

Water pressure regulators are installed in plumbing systems to maintain a consistent and safe water pressure level. When these regulators malfunction, it can lead to issues such as low or high water pressure. Being able to repair or replace faulty water pressure regulators is essential for a plumber.

Repairing a water pressure regulator may involve cleaning or replacing clogged screens or faulty components. Plumbers need to diagnose the specific issue and apply the appropriate repair method to restore proper regulation.

In some cases, a faulty water pressure regulator may require replacement. Plumbers need to have the skills to remove the old regulator, select a suitable replacement, and install it correctly. Proper installation ensures accurate pressure regulation and prevents future pressure-related issues.

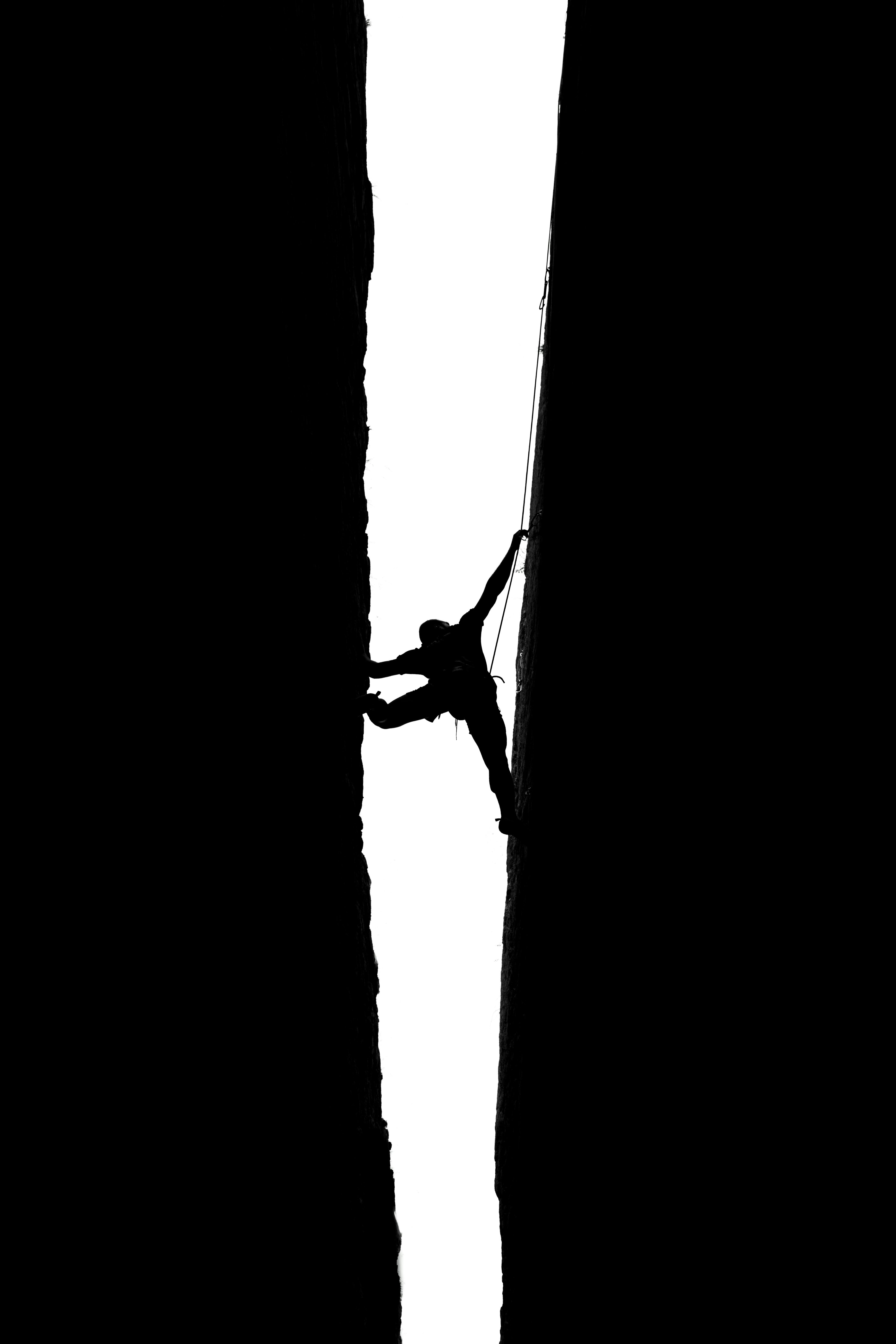

Working in Confined Spaces

Plumbers often encounter situations where plumbing tasks need to be performed in small, confined spaces. Working effectively in these spaces requires adaptability, patience, and knowledge of the specific challenges they present.

Performing plumbing tasks in small bathrooms

In residential settings, bathrooms are often the smallest rooms in the house. Plumbers may need to perform tasks such as installing fixtures, repairing pipes, or accessing shut-off valves in these tight spaces.

To work effectively in small bathrooms, plumbers need to utilize compact tools and techniques. They may need to remove toilets or access wall cavities to reach the plumbing components, requiring careful maneuvering in limited space.

Specialized tools and techniques, such as telescoping inspection mirrors or flexible wrenches, can help plumbers access confined areas and carry out the required tasks efficiently. Patience and attention to detail are crucial when working in small bathrooms to prevent damage to fixtures or other components.

Working in tight crawl spaces

Crawl spaces are often found in older homes and serve as access points to the plumbing system. These spaces can be cramped, dark, and difficult to navigate. Plumbers need to be prepared to work in tight crawl spaces to perform repairs or installations effectively.

Working in tight crawl spaces requires physical agility and the ability to maneuver in limited space. Plumbers may need to crawl or slide through small openings and use specialized tools to reach the plumbing components.

Safety precautions are essential when working in crawl spaces, as they can present hazards such as restricted ventilation, unstable flooring, or exposure to pests or mold. Plumbers need to have the knowledge and equipment to ensure their safety and protect their health while working in these challenging environments.

Repairing plumbing in basements or attics

Plumbing systems in basements or attics can be challenging to access and repair. Basements can have low ceilings or exposed beams, while attics can have limited headroom and insulation obstacles. Plumbers need to adapt their techniques to effectively repair plumbing in these areas.

Working in basements or attics often involves navigating through tight spaces and using specialized tools to access plumbing components. Plumbers may need to remove insulation, move stored items, or work around structural elements to reach the affected pipes or fixtures.

Understanding the layout of the plumbing system in basements or attics is crucial when determining the cause of the problem and planning the appropriate repair method. With careful planning and proper techniques, plumbers can effectively repair plumbing issues in these challenging locations.

Handling Emergency Situations

Plumbing emergencies can occur at any time and can cause significant damage if not addressed promptly. Being able to respond to emergency situations quickly and effectively is essential for a plumber.

Responding to burst pipes

Burst pipes can result from freezing temperatures, significant pressure changes, or aged plumbing materials. When a pipe bursts, it can cause extensive water damage and disrupt the water supply. Responding promptly to burst pipes is crucial to minimize the impact and prevent further damage.

Plumbers need to be prepared to handle burst pipes by having the necessary tools and materials readily available. Temporary repairs such as pipe clamps or pipe repair tape can be applied to stop the water flow and prevent additional damage until a permanent repair can be made.

Once the burst pipe is identified, plumbers need to have the skills to safely replace the damaged section of the pipe and restore the water supply. Properly sealing and securing the connection ensures a reliable and leak-free repair.

Dealing with flooding and water damage

When plumbing emergencies occur, such as burst pipes or malfunctioning appliances, they can result in flooding and water damage. Dealing with these situations requires prompt action to minimize the damage and restore the affected area.

Plumbers need to have the skills and equipment to extract water, dry affected surfaces, and assess the extent of the damage. They may work in collaboration with restoration professionals to ensure a thorough and effective recovery process.

Responding to flooding and water damage also involves identifying and addressing the root cause of the issue. Plumbers need to assess the plumbing system, identify potential vulnerabilities, and provide recommendations to prevent future incidents.

Repairing or replacing failed water heaters

When a water heater fails, it can lead to a lack of hot water, leaks, or even potential safety hazards. Responding to a failed water heater requires diagnosing the issue and implementing the appropriate repair or replacement method.

Plumbers need to assess the specific problem, whether it is a faulty thermostat, a gas valve issue, or a damaged heating element. Based on the assessment, they can decide whether to repair the existing water heater or replace it with a new one.

Replacing a failed water heater involves disconnecting the old unit, selecting an appropriate replacement with the desired capacity and energy efficiency, and installing it correctly. Proper installation ensures safe operation and the provision of hot water to the building.

Dealing with Hazardous Substances

Plumbing work can sometimes involve potentially hazardous substances that require careful handling and adherence to safety protocols. Being aware of and understanding how to work with these substances is crucial to protect both the plumber and the building occupants.

Working with potentially toxic chemicals

Plumbers may encounter potentially toxic chemicals when working with drain cleaners, pipe sealants, or other substances used in plumbing maintenance or repairs. These chemicals can be harmful if not used properly, requiring plumbers to follow safety guidelines and wear appropriate protective gear.

Plumbers need to have a thorough understanding of the potential risks associated with specific chemicals and the appropriate measures to take to minimize exposure. Proper ventilation, protective gloves, and eye protection are some of the safety precautions plumbers should take when working with potentially toxic chemicals.

It is also important for plumbers to be knowledgeable about environmentally friendly alternatives to toxic chemicals. This includes using natural drain cleaners or incorporating green plumbing practices that reduce the need for harmful chemicals.

Ensuring safety when dealing with asbestos pipes

In older buildings, asbestos pipes may be present in plumbing systems. Asbestos is a hazardous material that can cause severe health issues if its fibers are released into the air and inhaled. Plumbers need to be aware of the risks associated with asbestos and take appropriate safety measures when working with such pipes.

When dealing with asbestos pipes, plumbers should avoid disturbing the material as much as possible. If repairs or replacements are necessary, specialized procedures and equipment should be used to prevent the release of asbestos fibers.

Plumbers should receive appropriate training on asbestos safety and adhere to regulations and guidelines set by local authorities. This includes wearing protective clothing, using respiratory protection, and properly disposing of any materials that may contain asbestos.

Keeping Up with Advancing Technology

As technology advances, so does the plumbing industry. Staying informed about new plumbing tools and technologies is crucial for plumbers to provide the highest level of service to their clients.

Learning about and working with new plumbing tools

New plumbing tools are constantly being developed to improve efficiency, accuracy, and safety. Plumbers need to stay updated on the latest tools and equipment relevant to their field to enhance their capabilities and deliver high-quality work.

Tools such as pipe inspection cameras, electronic leak detectors, or hydro-jetting equipment can significantly assist plumbers in diagnosing issues and performing repairs more effectively. Familiarizing themselves with these tools and their proper use allows plumbers to provide efficient and accurate solutions to plumbing problems.

In addition to diagnostic tools, advancements in pipe materials, fittings, and joining methods also require plumbers to stay informed. Mastering these new technologies enables plumbers to offer clients the most up-to-date solutions and installations.

Understanding and implementing smart plumbing systems

Smart plumbing systems integrate technology and automation to enhance water management, improve energy efficiency, and enable remote monitoring and control. As a plumber, understanding and implementing smart plumbing systems is becoming increasingly important.

Smart plumbing systems can include devices such as smart thermostats, water leak detectors, or automated irrigation systems. These systems offer benefits such as energy savings, water conservation, and improved convenience.

Plumbers need to familiarize themselves with the installation, programming, and troubleshooting of smart plumbing systems. This includes understanding how these systems communicate with each other and how they can be integrated into existing plumbing infrastructure.

By embracing advances in technology, plumbers can stay ahead of the curve and provide clients with innovative solutions that enhance the performance and sustainability of their plumbing systems.

0 Comments